All of your products will be strictly tested here. Each test adds assurance to the quality of your products. Würth is Quality, we will provide you the products with best quality.

All of your products will be strictly tested here. Each test adds assurance to the quality of your products. Würth is Quality, we will provide you the products with best quality.

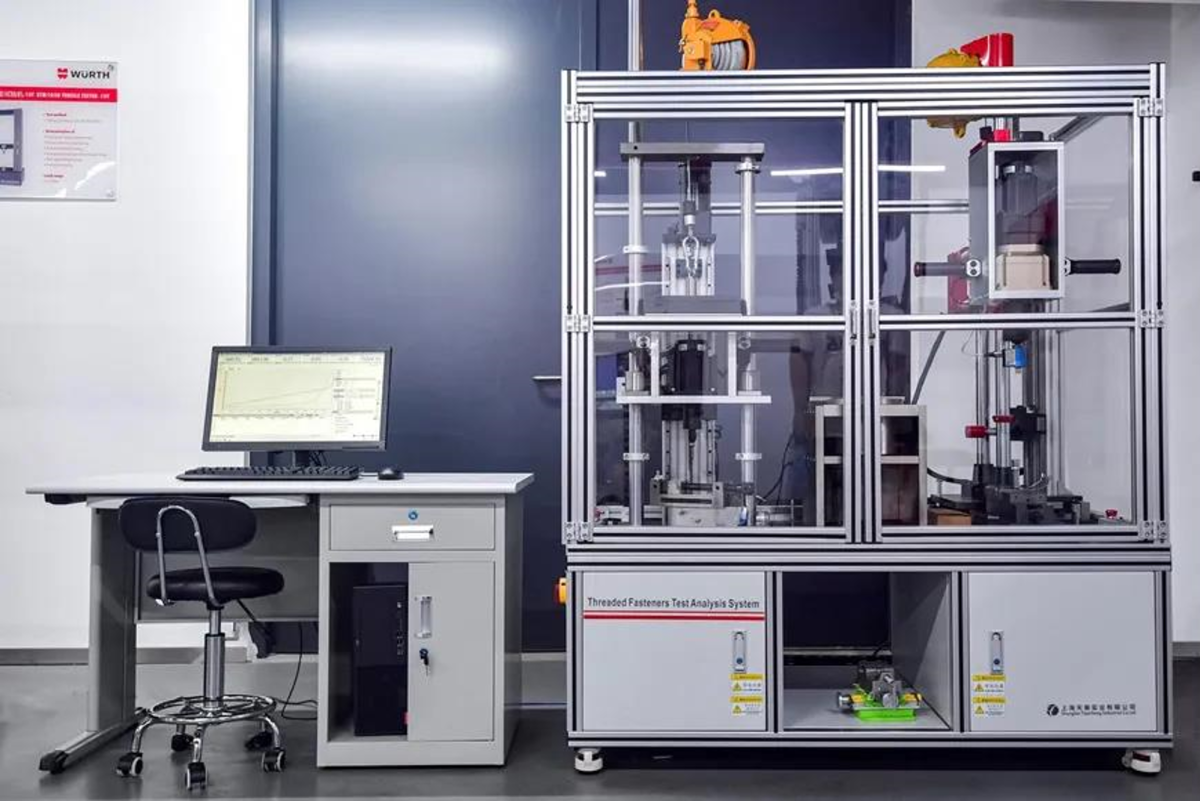

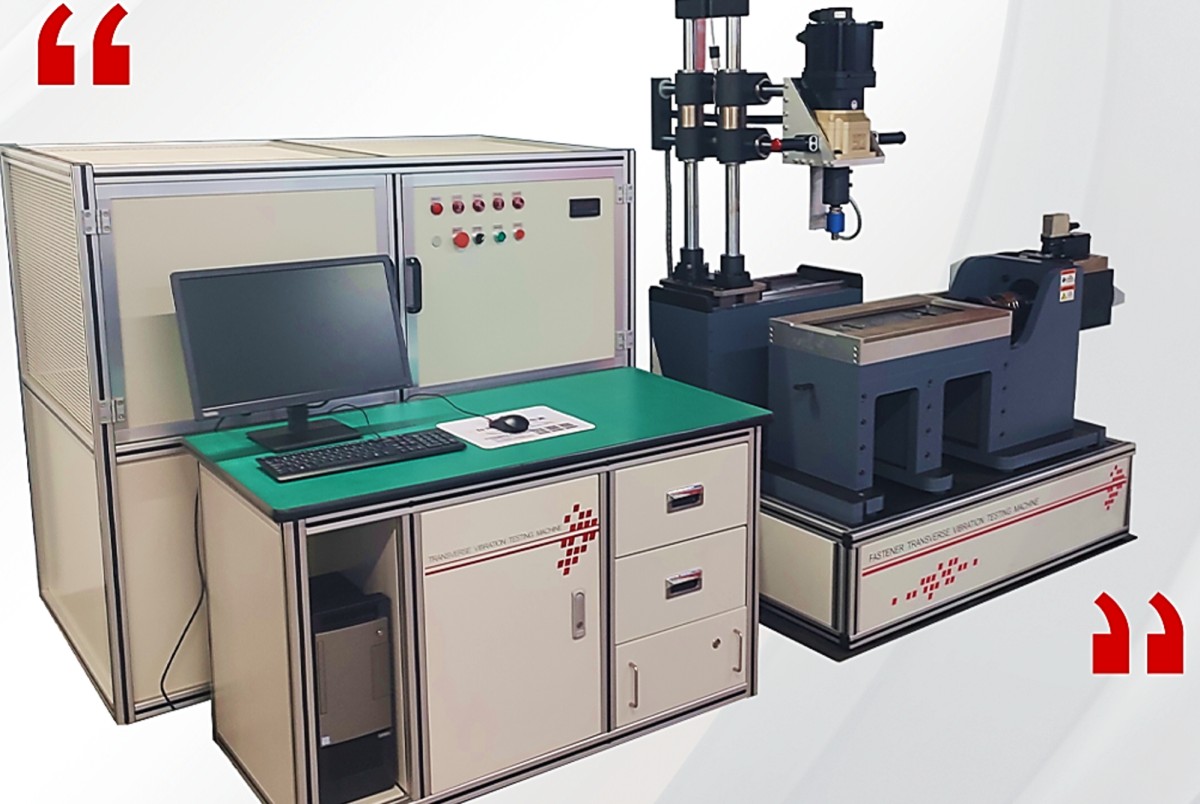

A Full Range of Test Types

Our Laboratory covers all major testing categories involved in international, domestic industry standards for fasteners, including dimension test, tensile test, impact test, hardness test, corrosion resistance test, torque test, locking performance test, friction test and so on. At the same time, Würth has always been at the forefront of science and technology. 3D scanners and 3D printers have been introduced to meet the growing needs of industrial customers.

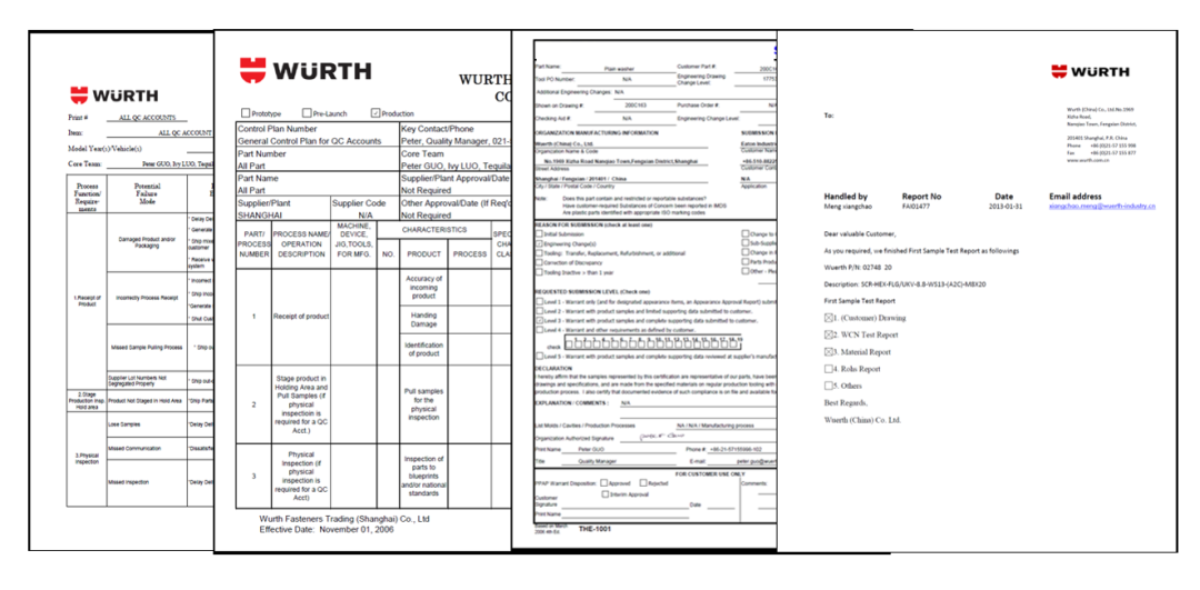

Professional Technical Support

Except for quality testing equipment and professional testing services, with our decades of accumulated expertise and experience in the field of connection technology, we can provide you with customized application technology solutions. The whole process from R & D to production will help you achieve the landing from the design to the product. It can effectively reduce the manufacturing cost for you while ensuring the quality and application safety.

Specialists in Connection Technology

Professionals are the cornerstone of enterprise development. Würth quality Lab has 21 inspection engineers who have obtained various qualifications such as mechanical properties, metallography and chemistry, with an average working experience of more than 8 years.