Additive Manufacturing

Based on 3D digital model layer by layer production molding, to help you quickly manufacture complex products.

Additive Manufacturing

Based on 3D digital model layer by layer production molding, to help you quickly manufacture complex products.

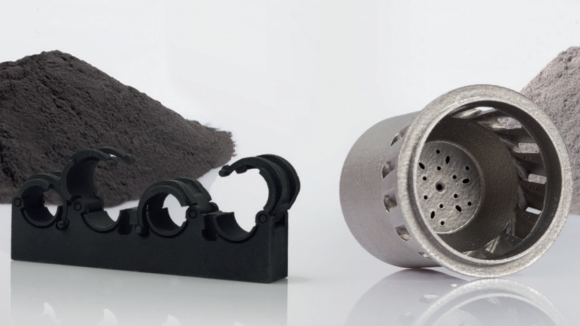

Principle of 3D Printing - Selective Laser Sintering (SLS)

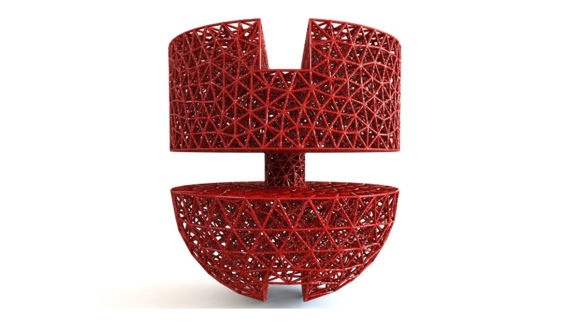

Polymer 3D printing

Technology: Selected Laser Sintering

Maximum Forming Size: 700x380x580mm

Minimum Forming Accuracy: +/- 0.1mm

| Material | Grade |

|---|---|

| Polyamide 12 | PA2200 |

| Polyamide 12 filled with Glass Beads | PA3200GF |

| Aluminum-filled Polyamide 12 | Alumide |

| Polyamide 12 with Halogen Flame Retardant | PA2241FR |

| Polyamide 12 with Halogen-free Chemical Flame Retardant | PA2210FR |

| Polyamide 11 | PA1101 |

| TPU | TPU1301 |

| Polypropylene | PP1101 |

| Polyether Ether Ketone | PEEK HP3 |

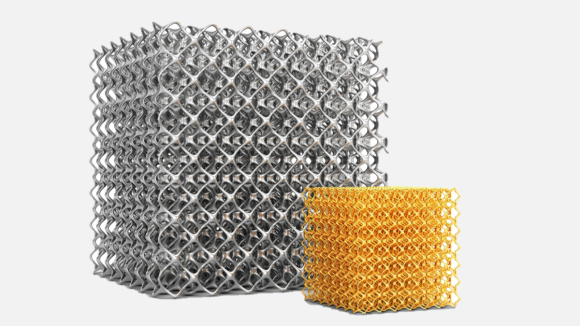

Metal 3D printing

Technology: Selected Laser Sintering

Maximum Forming Size: 400x400x400mm

Minimum Forming Accuracy: +/- 0.05mm

| Material | Grade |

|---|---|

| Stainless Steel | 316L |

| Tooling Grade Steel , | CX |

| Maraging Steel | MS1 |

| Aluminum Alloy | AlSi10Mg |

| Nickel Alloy | IN625 |

| Nickel Alloy | HX |

| Titanium Alloy | Ti64 |

| Titanium Alloy | Ti64Eli |